Blog Details

Construction Nails: Types, Applications and Supplier Guide

Construction Nails: Types, Applications and How to Choose the Right Nails

In the construction and building materials industry, construction nails are essential fastening products widely used in framing, roofing, pallet production and general structural applications. Choosing the right type of construction nail can significantly improve installation efficiency, structural strength and long-term durability.

This article introduces the main types of construction nails, their applications, and key factors to consider when sourcing from a reliable supplier.

What Are Construction Nails?

Construction nails are industrial-grade fasteners designed for heavy-duty use in building and structural applications. Unlike decorative or consumer nails, construction nails are manufactured to meet strict requirements for strength, holding power and corrosion resistance.

They are commonly used in:

-

Wood framing and structural assembly

-

Roofing and sheathing

-

Pallet and crate manufacturing

-

General construction and industrial packaging

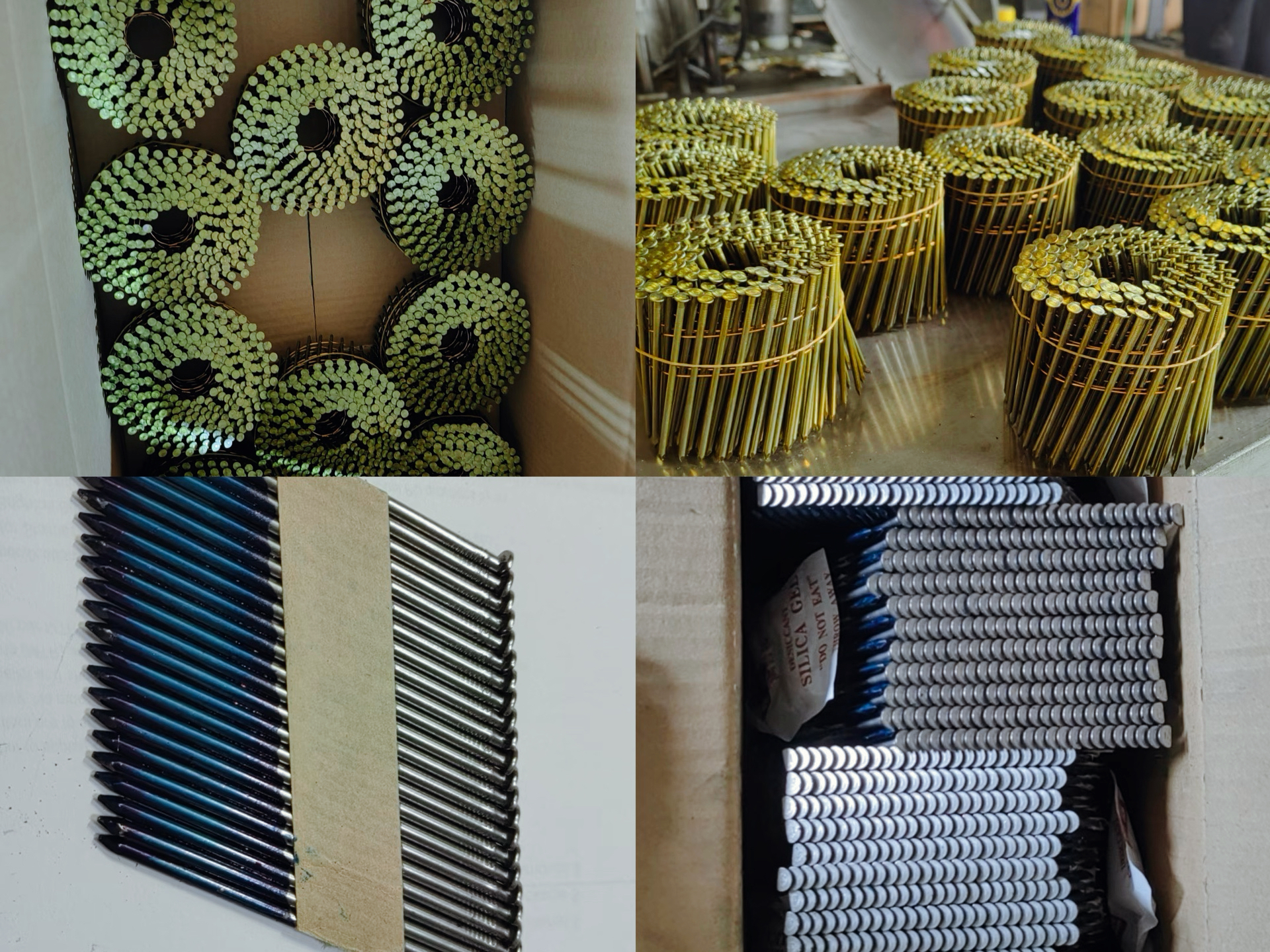

Main Types of Construction Nails

Paper Collated Nails

Paper collated nails are commonly used with pneumatic nail guns in framing and construction projects. The paper strip reduces debris during operation and is suitable for high-speed installation.

Typical applications:

-

Timber framing

-

Wall panels

-

Wooden structures

Coil Nails

Coil nails are connected by wire or plastic and supplied in coil form, allowing longer continuous operation with fewer reloads.

Typical applications:

-

Roofing

-

Fencing

-

Pallet and crate production

They are available in small head and large head designs, depending on application requirements.

Bulk (Loose) Common Nails

Bulk or loose nails are traditional construction nails used in manual or semi-automatic applications. They are widely used where flexibility and cost efficiency are required.

Typical applications:

-

General construction

-

Repair work

-

Industrial packaging

Surface Treatment Options

Construction nails are available with different surface finishes to meet various environmental conditions:

-

Bright finish – for indoor and dry applications

-

Electro-galvanized – basic corrosion resistance

-

Hot-dip galvanized – suitable for outdoor and humid environments

-

Mechanical galvanized – uniform coating with strong adhesion

Selecting the correct surface treatment helps extend product lifespan and ensures project reliability.

How to Choose the Right Construction Nails

When sourcing construction nails, buyers should consider:

-

Application requirements – framing, roofing or packaging

-

Nail size and diameter – according to load and material

-

Surface treatment – based on climate and exposure

-

Compatibility with tools – especially for collated nails

-

Supplier experience and quality control

A professional manufacturer can provide OEM specifications to meet regional standards and customer requirements.

Reliable Construction Nails Supplier

Shiny Industry is a professional manufacturer and exporter of construction nails, supplying paper collated nails, coil nails and bulk nails for global markets.

With stable quality control, OEM capability and export experience, we serve importers, distributors and construction material suppliers in Europe, the Middle East and other regions.

If you are looking for reliable construction nails for your projects or distribution business, please feel free to contact us for product details and quotations.

Powered by Shiny Industry CO., LTD